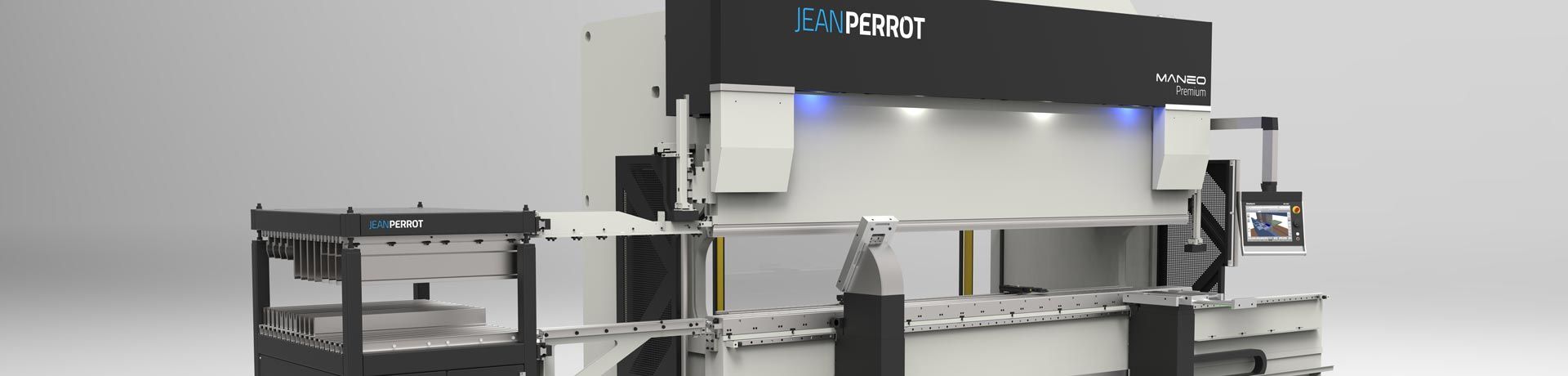

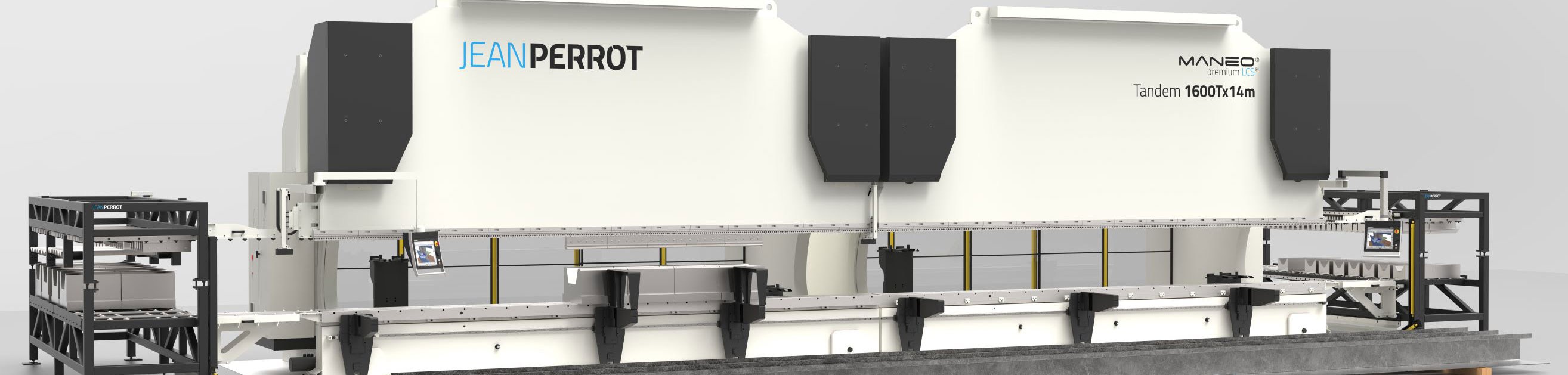

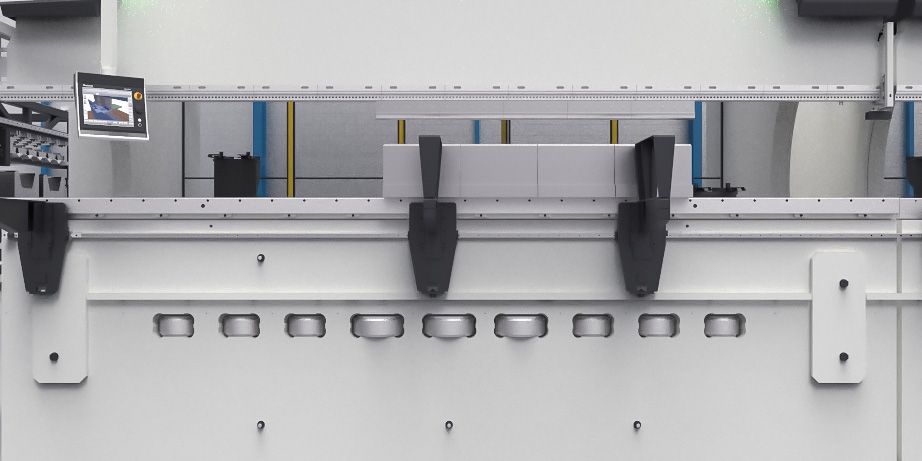

Press brakes MANEO Premium & MANEO Premium LCS

Sheet metal bending : Our press brakes MANEO Premium are high performance machines up to 2000 tons x 12 meters and more in Tandem or Tridem modes

. See More

Custom accessory equipment

We offer a wide range of standard & custom accessories in order to deliver turnkey press brake solutions adapted to your needs

See More

New electric press brake e-maneo

The essential for premium production E-MANEO premium can be distinguished by its modular, custom, and ecologically responsible design, high quality components, and ISO 9001 certified manufacturing procedures.

See More

Industry 4.0

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed a range of digitally enhanced services. Those services will assist you during the various phases of engineering development, operation, and maintenance.

See More

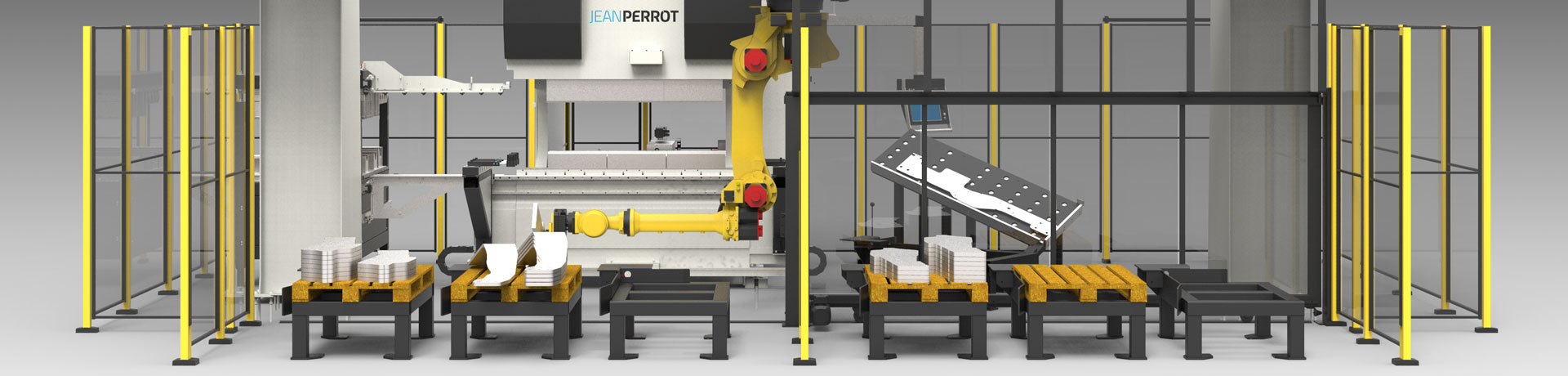

Automated bending: robotic press brake cell

We offer custom solutions to answer each of our clients' specific needs. Our automated bending cellsinclude press brake MANEO Premium LCS, robotic arms, accessories & additional modules to fit your needs.

See More

WELCOME TO JEAN PERROT

JEAN PERROT, a brand of PINETTE P.E.I. industrial engineering group, designs, manufactures and supplies sheet metal processing equipment : press brakes, automated robotic bending cells, shears, tube & profile benders, rolling machines, notching machines, punching machines…

From standard machines to turnkey automatic production lines including XXL heavy duty machines and custom tools, JEAN PERROT's team is at your disposal to define and answer all your needs related to sheet metal working machines.

‘’Innovation, expertise in sheet metal working processes and high quality of Jean Perrot’s services guarantee that your investment will be safe, mastered and adapted to your needs.’’

Retrofit by JEAN PERROT: retrofit services for press brakes, shears & other machines

JEAN PERROT is a brand of PINETTE industrial engineering group, specialized in standard or custom equipment and turnkey systems dedicated to profile & sheet metal processing. Among our solutions, discover the Retrofit by Jean Perrot: a service dedicated to renovating press brakes, shears, numerical control devices, equipment accessories and other machines dedicated to the transformation of sheet metal and profiles.

RETROFIT by JEAN PERROT

Whatever your need: Preventive maintenance actions, upgrades or adaptations of the machine to ensure compliance with the latest standards (including CE certification), actions following corrective maintenance or optimizing machine efficiency, JEAN PERROT provides a wide range of retrofit services for your press brakes, shears & other machines:

- Hydraulic: Directional control hydraulic valve, non return valve...

- Mechanical : mechanic gauge, ball bearings, tooling, protectors….

- Integration of the LCS laser control system allowing automatic bend angle measurement & correction

- Adding hydraulic dynamic crowning system

- Integration of accessories & peripheral equipment on existing machines & lines : conveyors, robots, tool storage systems….

- Lasers and safety sensors

- Safety programmable controllers (Safety PLC)

- Numerical controls and positioners (DELEM, CYBELEC, ESA, SIEMENS)

- Moving & re-starting your machines & lines

Whatever your need related to the retrofit of your press brakes, shears and other machines dedicated to profile & sheet metal working, do not hesitate to contact us or to send us an online request for quotation.

Training for machine operators & maintenance technicians

Proper use of your machines ensures optimal productivity, extends the equipment's operating life and reduces costs related to breakdowns due to poor use. For all this reasons, JEAN PERROT offers customised training services for machine operators and maintenance technicians.

JEAN PERROT: MACHINE TRAINING SERVICES WITH ACCREDITED TRAINERS

We are aware that it is more and more difficult to find qualified machine operators. Moreover, as for experienced car drivers, it is common to see experienced operators who have taken bad habits and who do not use their equipment properly.

To solve these issues, discover JEAN PERROT training services:

For your press brakes, your shears and any other machine dedicated to profile & sheet metal working, your machine operators & maintenance technicians can attend trainings from one of our accredited trainers. Our training courses cover:

- General training on how to use our equipment

- Machine maintenance

- Numerical controls

- Bending software

- Customized training on request

Whatever your need related to the training of your staff on our machines dedicated to profile & sheet metal working, do not hesitate to contact us or to send us an online request for quotation.

Spare parts, consumables, tooling & related after-sales service for press brakes, shears and other machines

With JEAN PERROT customer service, you can order your spare parts, consumables & tools for press brakes, shears and other machines dedicated to profile & sheet metal working. We also offer a range of after-sales services related to spare parts & consumables replacement.

SPARE PARTS - CONSUMABLES - TOOLS

We sell all types of spare parts and consumables:

- Mechanical

- Hydraulic

- Electric

- Press brake tooling

- Shear blades

Check out our catalogue to find the spare parts or consumables that you need & place your order online, by email or phone.

RELATED AFTER SALES SERVICES

Our technicians are trained to carry out any after-sales service task you may need:

- Replacement of spare parts, consumables & machine tooling

- Shear blade flips

- Cylinder seal replacement

- Electrical testing

- Selling & replacement of components

- ...

Do you have another need? Do not hesitate to contact us or to send us an online request for quotation.

Remote control for press brakes: touchscreen tablet

As part of its innovation strategy dedicated to industry 4.0 JEAN PERROT can provide a touchscreen tablet that will allow CNC press brake remote control by displaying the CNC interface on the tablet.

TOUCHSCREEN TABLET FOR REMOTE CONTROL

We can optionally provide an industrial tablet that will be directly connected to the numerical control system of the press brake. With this solution, you will manage all CNC control functions for a press brake real-time control. The operator can carry out all its tasks easily while maintaining the remote control on the DELEM CNC.

Ideal for tasks at the center of the machine or far from the CNC control. This tablet is particularly useful for tandem press brakes and large machines. It allows to be close to press brake tools & workpieces (when they need adjustments) without losing time. The tablet can be attached with shoulder strap or fixed on the machine with magnets.

Would you like to know more about our touchscreen tablet for cnc press brake remote control ? Do not hesitate to contact us or to send us an online request for quotation.

Rear belt conveyor for shearing machines

Industrial shears dedicated to sheet metal cutting represent an important part of our activity. In order to complement this product line, we have developed a rear belt conveyor with return to the front system which allows to simplify the operator’s tasks while optimizing the performance of our shearing machiness.

REAR CONVEYOR WITH RETURN TO THE FRONT SYSTEM

The rear belt conveyor (single or multiple driven belt conveyors) simplifies not only the cutting step but also upstream & downstream operations :

The rear belt conveyor (single or multiple driven belt conveyors) simplifies not only the cutting step but also upstream & downstream operations :

- Maintaining sheet metal during positioning step

- Supporting sheet metal during the cutting step

- Sheet metal storage

- Sheet metal transfer toward the front or the back of the machine

- Evacuation of trim cuts in a scrap container

- 2 ways to set conveyor belt(s) operating features : time or speed.

Would you like further information? Whatever your project regarding shearing machines & accessories, do not hesitate to contact us or to send us an online request for quotation.

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed a range of digitally enhanced services. Those services will assist you during the various phases of engineering development, operation, and maintenance.

Industry 4.0

Engineering development: Virtual Reality Project Engineering

Our Virtual Reality package empowers you to visualise in 3D and to scale your new piece of equipment during the design and engineering phase. Operation and maintenance ergonomics can be simulated for increased productivity and reduced labour related injuries. Co-engineering is made easier and can involve all the stakeholders. You can start training your operators before your equipment is delivered to you. Finally, it gives you the opportunity to communicate with your teams, partners, customers, etc.

- 3D and to scale visualisation

- Design reviews

- Ergonomics

- Co-engineering

- Training

- Communication

Operations: myJEANPERROT Remote monitoring

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed an application which enables you to remotely monitor your JEAN PERROT equipment in real time. Connected to your machine, you can monitor your production and performances, hence improve overall efficiency. Maintenance is also connected; you are notified instantaneously and can monitor breakdowns. You can then immediately solicit assistance through the application.

myJEANPERROT application enables you to connect with your JEAN PERROT equipment for:

- Better monitor your production

- Improve efficiency

- Get performance diagnosis

- Get equipment alarms through push notifications

- Log data breakdowns/breakdown historic

- Solicit assistance

Maintenance: Vision Pack

JEAN PERROT’s Vision Pack is the state-of-the-art in technical support. It eases maintenance procedures through Augmented Reality. In the event of a breakdown, our specialists will guide you step by step. He will project schemes and instructions through the glasses so your technicians can work with both hands. It is like our experts are with you in your workshop: they see what you see in real-time. Thus, downtimes are drastically reduced, so are support costs.

The Vision Pack for maintenance enables you to:

- Work with both hands

- Expand JEAN PERROT technical support’s reach

- Troubleshoot with efficiency

- Reduce downtimes

- Minimise support costs

- Maximise effectiveness

- Provide best know-how

These solutions are already available in our after-sales service department. They are available via a subscription to our premium 4.0 maintenance contract.

If you would you like to know more about our solution 4.0, do not hesitate to contact us or to send us an online request for quotation.

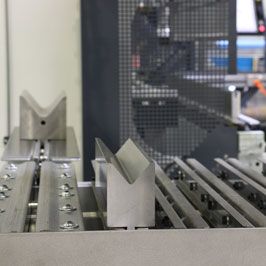

Bending aid for press brake: sheet metal followers

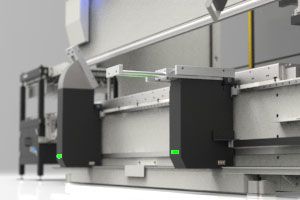

We believe in innovation and continuous improvement. For these reasons, JEAN PERROT has created new motorised sheet followers to support the sheet during the bend, avoiding excessive deformation. These accessories optimize the bending performances of MANEO Premium & Premium LCS press brakes and simplify machine operators’ work.

SHEET METAL FOLLOWERS

The latest followers for sheet metal bending aim to optimize the performances of our press brakes by reducing the time to set up the press brake and simplifying the work of operators.

The latest followers for sheet metal bending aim to optimize the performances of our press brakes by reducing the time to set up the press brake and simplifying the work of operators.

These bending aids provide valuable practical assistance (including an automatic height adjustment) for operators especially for heavy or large parts. Discover the main features of our sheet metal followers:

- Light solution, easy to move

- Adjustable according to the size of the workpiece

- Active or inactive modes that can be controlled directly on the sheet follower to avoid any safety risks (LED light located on the sheet follower)

Would you like to know more about our sheet metal followers ? Do not hesitate to contact us or to send us an online request for quotation.

Press brake accessories: production traceability & barcode reader

JEAN PERROT has developed a traceability system and a barcode reader adapted to its press brakes. It simplifies production changeovers as well as workpiece & finished part management.

BARCODE READER FOR PRESS BRAKES

Barcode reader for press brakes can be used for a wide range of applications. The first one is to load a bending program associated to the scanned blank. With this solution, there is no more error in the bending program choice nor losses of time to find the good bending program if you have several storage areas.

Barcode reader for press brakes can be used for a wide range of applications. The first one is to load a bending program associated to the scanned blank. With this solution, there is no more error in the bending program choice nor losses of time to find the good bending program if you have several storage areas.

Moreover, you can integrate specific data (related to operators, positions...) without having to write down data but by simply scanning the barcode containing prefill data already known by the traceability system in place. Our system also allows to archiving the traceability of single parts or complete product lines (.txt or .xls formats).

Would you like to know more about our traceability system & barcode readers for press brakes? do not hesitate to contact us or to send us an online request for quotation.

Hydraulic dynamic crowning for press brake

If precision is one of the most important features of a press brake, it is almost impossible to completely avoid very small imperfections compared with the bending angle originally desired, especially for heavy, long or large parts.

To solve this problem, JEAN PERROT press brakes can be equipped with a dynamic crowning system. This compensation system adjusts the curvature of the lower beam automatically during the bending phase. It enables to reach perfect bending results (equal & consistent angles) all along the length of the bend.

HYDRAULIC VS MECHANICAL CROWNING

The crowning system is a motorized or hydraulic axis which adjusts the curvature of the lower beam automatically during the bending phase. The crowning effort is calculated from a specific formula and from machine's setting adjustments. Depending on the type of part to be bend (bending on one side of the machine rather than bending on the center of the press brake…..) corrections can be made.

Unlike mechanical crowning system which is positioned before the bending phase, the hydraulic crowning system allow real time compensation.

Features of the CNC hydraulic crowning system:

During the bending phase, the correct crowning is calculated by the CNC and applied in real time, based on direct feedback from pressure sensors located in the press brake’s ram & bed. The multiple hydraulic crowning cylinders located within the lower bed frame allow to counter the ram deflection.

JEAN PERROT can equip its press brakes with CNC hydraulic crowning systems offering great performance : up to 800 tons per meter (option).

Would you like to know more about our hydraulic crowning system for press brakes? do not hesitate to contact us or to send us an online request for quotation.

Toolbox: press brake tool storage, loading & unloading

Toolbox: press brake tool storage, loading & unloading

Reducing the time & simplifying the tasks to set up press brakes between completing one batch of parts and starting the next one: here are two of the main needs of the sheet metal working industry.

To answer these needs, JEAN PERROT developped an innovative tool storage solution dedicated to press brake standard & custom tooling : the ToolBox (modular system for tool storage, loading & unloading).

TOOLBOX: press brake tool storage, loading & unloading

The interface between the press brake and the ToolBox is ensured by 2 loading / unloading arms with roller & ball bearing system. It enables all sizes of punches & dies to be quickly, effortlessly & safely stored, loaded & unloaded. With our system, the working conditions of your operators will be improved and your productivity optimized.

ToolBox : innovative modular concept for press brake tool management

ToolBox is a modular tool storage station that can be set to suit any configuration & use:

- Implementation on the right or left side of the press brake

- Possibility to increase storage capacity with additional modules

- Double input model available

- XXL ToolBox model available for large & heavy duty press brakes

- Easy management not only for punches & dies but also for special tools such as hemming tables…

Would you like further information ? Whatever your need related to press brake tool storage, loading & unloading, do not hesitate to contact us, to download the brochure or to send us an online request for quotation.

HIGHLIGHTS

News

Presse review: JEAN PERROT IN ISMR

JEAN PERROT in the pages of International Sheet Metal Review

As part of the LAMIERA 2023 trade show in Milan, where our Italian subsidiary

Tolexpo 2021

Jean Perrot at Tolexpo 2021

Come and meet us from 6th to 9th September at Global Industry at Eurexpo Lyon!

booth 6G36

You will discover our cutting edge technologies and pro...