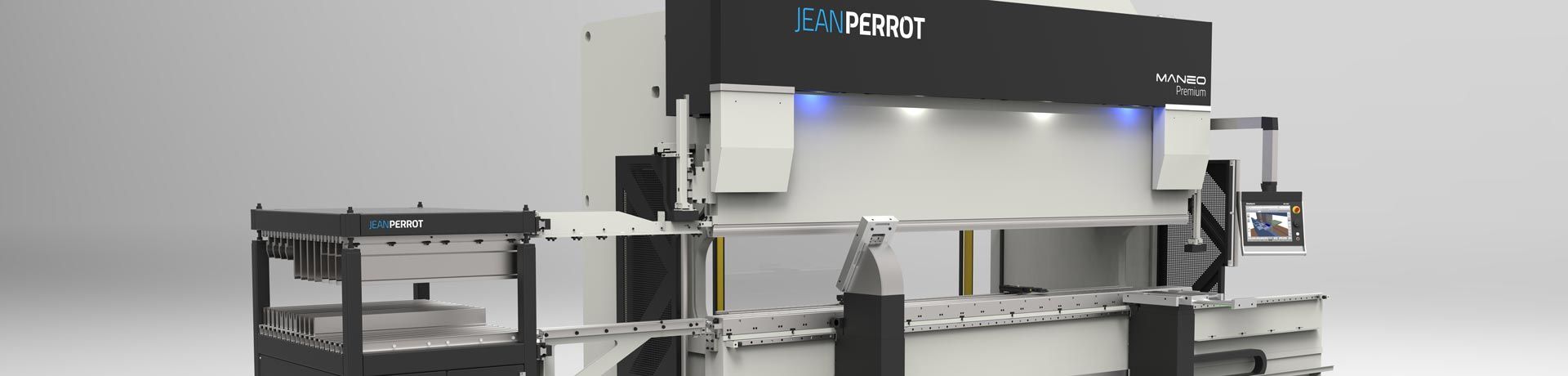

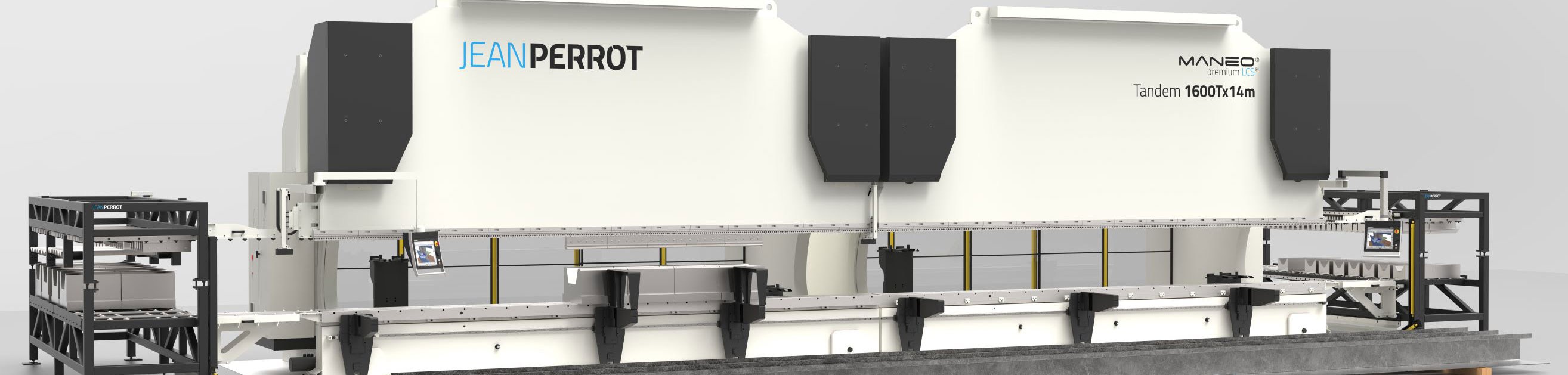

Press brakes MANEO Premium & MANEO Premium LCS

Sheet metal bending : Our press brakes MANEO Premium are high performance machines up to 2000 tons x 12 meters and more in Tandem or Tridem modes

. See More

Custom accessory equipment

We offer a wide range of standard & custom accessories in order to deliver turnkey press brake solutions adapted to your needs

See More

New electric press brake e-maneo

The essential for premium production E-MANEO premium can be distinguished by its modular, custom, and ecologically responsible design, high quality components, and ISO 9001 certified manufacturing procedures.

See More

Industry 4.0

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed a range of digitally enhanced services. Those services will assist you during the various phases of engineering development, operation, and maintenance.

See More

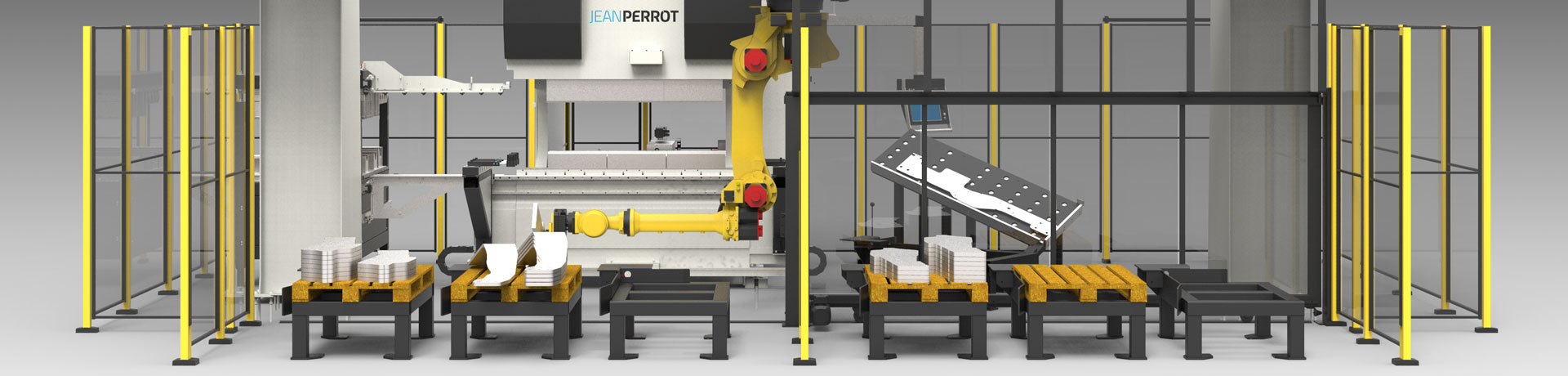

Automated bending: robotic press brake cell

We offer custom solutions to answer each of our clients' specific needs. Our automated bending cellsinclude press brake MANEO Premium LCS, robotic arms, accessories & additional modules to fit your needs.

See More

WELCOME TO JEAN PERROT

JEAN PERROT, a brand of PINETTE P.E.I. industrial engineering group, designs, manufactures and supplies sheet metal processing equipment : press brakes, automated robotic bending cells, shears, tube & profile benders, rolling machines, notching machines, punching machines…

From standard machines to turnkey automatic production lines including XXL heavy duty machines and custom tools, JEAN PERROT's team is at your disposal to define and answer all your needs related to sheet metal working machines.

‘’Innovation, expertise in sheet metal working processes and high quality of Jean Perrot’s services guarantee that your investment will be safe, mastered and adapted to your needs.’’

HYDRAULIC PUNCHING MACHINE

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to sheet metal processing. Other than press brakes, shears, benders, rollers & punching machines, we supply hydraulic punching machines for sheet metal, steel plates & profiles.

HYDRAULIC PUNCHING MACHINE FOR METAL SHEETS, STEEL PLATES & PROFILES

The steel construction welded frame of JEAN PERROT hydraulic punching machines ensures punching precision and quality while guaranteeing the operator’s safety. Machine models: 65 T / 85 T / 115 T / 175 Tons.

In order to improve your productivity, JEAN PERROT punching machines can be equipped with different accessories and options: 1400 x 1000 mm table with automatic positioner, additional tool sets….

According to your needs, our hydraulic punching machines can be composed of:

- 1 or 2 punching heads

- Punch holder

- Manual control or CNC machines

- Start and stop control with foot pedal

- Lateral guides

- Scrap collecting system

- Working light

- C-spanner to change punches

- Protectors & guards to ensure operator’s safety

Would you like to know more? Whatever your need regarding punching machines, do not hesitate to contact us or to send us an online request for quotation.

Hydraulic notching machines: Sheet metal notchers

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to sheet metal processing. Other than press brakes, shears, benders, rollers & punching machines, we supply hydraulic notching machines with variable angle.

SHEET METAL NOTCHING : VARIABLE ANGLE NOTCHERS

Our hydraulic variable angle notching machines allow simple and fast cutting of steel sheets up to 6 mm thick and stainless steel sheets up to 3 mm thick.

Features of our notching machines:

- 2 hand wheels to set eadily the notching angle

- Protractor to adjust precisely the notching angle

- Squaring guides, scales, and angle gauge.

- Automatic blade gap adjustment for all sheet thicknesses.

- Optimal safety for operators thanks to front, back & side protectors

- Scrap collecting system

Notching capacities and other capacities:

- Cutting length up to 200 mm

- Cutting thickness capacity up to 6 mm for a density of 42 kg / mm 2

- Cutting thickness capacity up to 3 mm for a density of 70 kg / mm2

- Cutting angle: 5°

- Notching angle (3 mm): 30-140°

- Cuts per minute: 50

Would you like to know more ? Whatever your project regarding sheet metal notching machines, do not hesitate to contact us or to send us an online request for quotation.

Rolling machines: sheet metal rollers

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to sheet metal processing. Other than press brakes, shears, benders, notchers & punching machines, we supply sheet metal rolling machines.

HYDRAULIC OR ELECTRIC SHEET METAL ROLLING MACHINES

Depending on your project, we can supply manual, electric or hydraulic rolling machines with 2, 3 or 4 rolls. JEAN PERROT sheet metal rollers have the capacity to prebend leading and trailing edges without removing the workpiece from the machine.

Other advantage, the bottom roll inclination allows conical bending. In order to better respond to your needs, we supply sheet metal rollers with 1, 2 or 3 driven rolls.

As an industrial engineering company specialised in sheet metal working processes, JEAN PERROT can supply a large range of equipment accessories and peripheral equipment to ensure the automatic loading and unloading. We can also design and manufacture turnkey automatic lines dedicated to sheet metal & plate rolling.

Features & strengths for our rolling machines:

- Manual, electric or hydraulic machines

- 2, 3 or 4 rolls

- CNC machines

- Sheet thickness min-max: 0.8 to 60 mm

- Sheet length min-max: 1050 to 6000 mm

- Mobile control panel

- Modular design: large range of accessories & peripheral equipment available.

Would you like to know more ? Whatever your project regarding rolling machines & sheet metal rollers, do not hesitate to contact us or to send us an online request for quotation.

Bending machines: bar, pipe, profile & tube benders

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to sheet metal processing. Other than press brakes, shears, rollers, notchers & punching machines, we supply bar, pipe, profile & tube bending machines.

BENDING MACHINES: BAR, PIPE, PROFILE & Tube BENDERS

Standard or customized, JEAN PERROT motorized rolls bending machines ensures reliability, versatility & precision. According to your needs, we can supply hydraulic or electric bending machines.

It is also possible to equip these benders with specific rolls in order to bend all sizes of tubes, pipes, profiles and bars.

Finally, to facilitate the operator's tasks and to reach optimal precision and flexibility, our bending machines can be supplied with numerical control device.

Features & strengths for our bending machines:

- Horizontal or vertical operating position

- L-profile & corner size from 40 to 250 mm

- Hardened rolls

- Mobile control panel

- Easy to use / control for operators

- Robust design

- Precision

Would you like to know more? Whatever your project regarding bending machines & benders for tubes, pipes, bars and profiles, do not hesitate to contact us or to send us an online request for quotation.

Sheet metal processing: more machines

In order to provide a comprehensive range of solutions, discover more machines dedicated to sheet metal processing. Other than press brakes & shears, JEAN PERROT designs, manufactures & supplies : tube & profile bending machines, sheet metal rolling machines, notching and punching machines.

BENDING MACHINES : Bar, PROFILE, PIPE & TUBE BENDERS

BENDING MACHINES : Bar, PROFILE, PIPE & TUBE BENDERS

Standard or customized, JEAN PERROT benders ensure reliability, versatility & precision. According to your needs, we can supply hydraulic or electric bending machines.

ROLLING MACHINES : SHEET METAL ROLLERS

ROLLING MACHINES : SHEET METAL ROLLERS

Depending on your project, we can supply manual, electric or hydraulic rolling machines with 2, 3 or 4 rolls. JEAN PERROT's sheet metal rollers have the capacity to prebend leading and trailing edges without removing the workpiece from the machine.

VARIABLE ANGLE NOTCHING MACHINE

VARIABLE ANGLE NOTCHING MACHINE

Our hydraulic variable angle notching machines allow simple and fast cutting of steel or stainless steel sheets.

HYDRAULIC PUNCHING MACHINES

HYDRAULIC PUNCHING MACHINES

According to your needs, we can supply punching machines from 65 to 175 tons. These machines can be equipped with accessories & peripheral equipment in order to form a turnkey punching line.

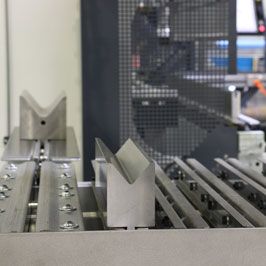

Press brake tooling : tool storage solutions

Reducing the time & simplifying the tasks to set up press brakes between completing one batch of parts and starting the next one: here are two of the main needs of the sheet metal working industry.

To answer these needs, JEAN PERROT provides innovative tool storage solutions dedicated to press brake standard & custom tooling : the ToolBox (modular tool storage & changing system) and standard tooling cabinets.

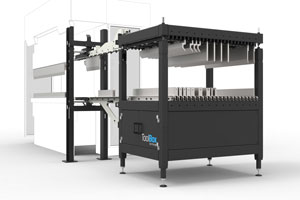

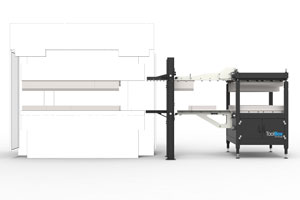

TOOLBOX: press brake tool storage, loading & unloading

The interface between the press brake and the ToolBox is ensured by 2 loading / unloading arms with roller & ball bearing system. It enables all sizes of punches & dies to be quickly, effortlessly & safely stored, loaded & unloaded. With our system, the working conditions of your operators will be improved and your productivity optimized.

ToolBox : innovative modular concept for press brake tool management

ToolBox is a modular tool storage station that can be set to suit any configuration & use:

- Implementation on the right or left side of the press brake

- Possibility to increase storage capacity with additional modules

- Double input model available

- XXL ToolBox model available for large & heavy duty press brakes

- Easy management not only for punches & dies but also for special tools such as hemming tables…

ToolBox is compatible with all brake presses

You do not own a JEAN PERROT brake press? No problem. ToolBox adapts to every brake press brand.

Press brake tool storage cabinets

We also provide press brake tooling cabinets to store your dies & punches:

We also provide press brake tooling cabinets to store your dies & punches:

- Up to 5 drawers & more on request

- Drawers can be divided into compartments (up to 5)

- Black or customized color (option)

Would you like further information? Whatever your need regarding press brake tool storage, loading or unloading, do not hesitate to contact us or to send us an online request for quotation.

Press brake custom tool solutions & specific tooling

In addition to standard tooling, we can help you to define & design custom engineered tools for your specific applications and we can manufacture and supply these special tools. From your part drawings, our design department can create custom tools dedicated to your specific production needs.

Press brake custom engineered tool solutions

Designer, manufacturer & supplier of custom press brakes and custom tools for over 50 years, JEAN PERROT is able to create a large range of special tools dedicated to your sheet metal processing press brake:

Designer, manufacturer & supplier of custom press brakes and custom tools for over 50 years, JEAN PERROT is able to create a large range of special tools dedicated to your sheet metal processing press brake:

- Special punches

- Special dies

- Hemming tables

- Variable V-opening press brake die (manually or motorized)

- Rotating tools

- Special tools for bottom bending

- U channel bending tools

- Tools for electric poles ... (conical or polygonal shapes)

Custom tools to perfectly fit your needs

We design & manufacture tools for over 50 years. Thanks to this experience, we can define tool features that will perfectly fit your needs:

- Tool material tailored to your real need

- Heat treatment adapted to your applications

- Surface roughness inspection

CAD software to design custom & special tools

All our special tools are designed with our CAD software, validated by a strength of material calculation software and registered in order to guarantee:

- Better traceability

- Tool repair from original drawing

- Complete or partial replacement of the tool section

- Tool modification with original drawing update

Would you like further information? Whatever your need regarding press brake special tool solutions, do not hesitate to contact us or to send us an online request for quotation.

Press brake standard tooling: punches & dies

JEAN PERROT provides a large range of standard or custom tools for press brake (punches, dies…) as well as tool storage solutions. If you want us to replace your tools, please do not hesitate to contact our after sales service.

STANDARD TOOLING SOLUTIONS: punches & dies

We provide a complete range of tools for your press brake:

- PERROT range

- EURO range

- WILA range

- Tools from other brands

- Custom tools

Online catalogue : Press brake tooling - Online request for quotation

Would you like further information? Whatever your need regarding press brake tooling solutions, do not hesitate to contact us or to send us an online request for quotation.

Sheet metal working: general contractor for complex projects & turnkey plants

JEAN PERROT, a brand of PINETTE industrial engineering group, designs and manufactures standard or custom equipment and turnkey systems dedicated to sheet metal processing: press brakes, shears, profile & tube benders, rolling, notching & punching machines.

We benefit from the extent of the PINETTE group’s know-how in industrial engineering. Combined with our expertise of sheet metal working processes, it allows us to act as a general contractor and to carry out complex project and turnkey plants.

| Business Activities | Technologies |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A GENERAL CONTRACTOR FOR COMPLEX PROJECTS TURNKEY PLANT SOLUTIONS

Overall Project Management

As a general contractor, JEAN PERROT offers its customers turnkey solutions from research & needs analysis to on-site supervision including local & international sourcing and subcontractors supervision. A comprehensive single-source approach, project management, design & construction supervision, compliance to international and local regulations and commitment to performance objectives make JEAN PERROT the perfect partner for your turnkey plant.

As a general contractor, JEAN PERROT offers its customers turnkey solutions from research & needs analysis to on-site supervision including local & international sourcing and subcontractors supervision. A comprehensive single-source approach, project management, design & construction supervision, compliance to international and local regulations and commitment to performance objectives make JEAN PERROT the perfect partner for your turnkey plant.

Engineering & Design

From mechanical engineering to hydraulics, including robotics, industrial IT, data acquisition system (HMI supervision) and thermal engineering, JEAN PERROT takes care of the whole design & engineering through general arrangement drawings, bill of materials, specifications and quality control spreadsheets.

From mechanical engineering to hydraulics, including robotics, industrial IT, data acquisition system (HMI supervision) and thermal engineering, JEAN PERROT takes care of the whole design & engineering through general arrangement drawings, bill of materials, specifications and quality control spreadsheets.

Supply Chain Management

JEAN PERROT supervises logistics and administrative procedures until equipment is delivered onto client premises. Our experience and network of international subcontractors enable us to provide local solutions for equipment supply and manufacturing, reducing delivery times, associated costs and emission levels.

JEAN PERROT supervises logistics and administrative procedures until equipment is delivered onto client premises. Our experience and network of international subcontractors enable us to provide local solutions for equipment supply and manufacturing, reducing delivery times, associated costs and emission levels.

Construction & Commissioning

JEAN PERROT's integrators skills and experience on construction & commissioning are based on hundreds of turnkey projects implemented all around the world. It gives us the ability to mentor and supervise local teams to carry out successfully our missions. Concurrently, we ensure an input quality control to assess the suitability of the final assembly with customers’ specifications.

JEAN PERROT's integrators skills and experience on construction & commissioning are based on hundreds of turnkey projects implemented all around the world. It gives us the ability to mentor and supervise local teams to carry out successfully our missions. Concurrently, we ensure an input quality control to assess the suitability of the final assembly with customers’ specifications.

Would you like further information? If you are looking for a general contractor to manage complex projects such as complete production lines or turnkey plant construction, do not hesitate to contact us or to send us an online request for quotation.

Press brakes & machine troubleshooting | Jean Perrot technical support

If well-trained operators and regular preventive maintenance actions ensure that breakdowns are kept to a minimum, there is no zero risk ! For these rare cases, JEAN PERROT experienced after-sales service engineers & technicians are there to support you and to repair your breakdown as soons as possible.

JEAN PERROT SUPPORT THROUGHOUT THE TROUBLESHOOTING PROCESS

Regardless of your problem, JEAN PERROT is committed to supporting its customers from the very first call (or email) until the problem is fixed. According to the problem, JEAN PERROT can provide different types of corrective maintenance solutions:

- Hotline support : 1st diagnosis and breakdown resolution if possible

- On-site repair

We provide troubleshooting service on any of the following machines:

- ¨Press brakes

- Shears

- Bar, pipe, profile & tube benders

- Sheet metal rollers

- Notching machines

- Punching machines

Contact technical support service

Contact: Benoît Cartigny

Email:

Phone 1: + 33 - (0)3 - 85 - 47 - 88 - 62

Phone 2: + 33 - (0)7 - 61 - 13 - 14 - 59

HIGHLIGHTS

News

Presse review: JEAN PERROT IN ISMR

JEAN PERROT in the pages of International Sheet Metal Review

As part of the LAMIERA 2023 trade show in Milan, where our Italian subsidiary

Tolexpo 2021

Jean Perrot at Tolexpo 2021

Come and meet us from 6th to 9th September at Global Industry at Eurexpo Lyon!

booth 6G36

You will discover our cutting edge technologies and pro...