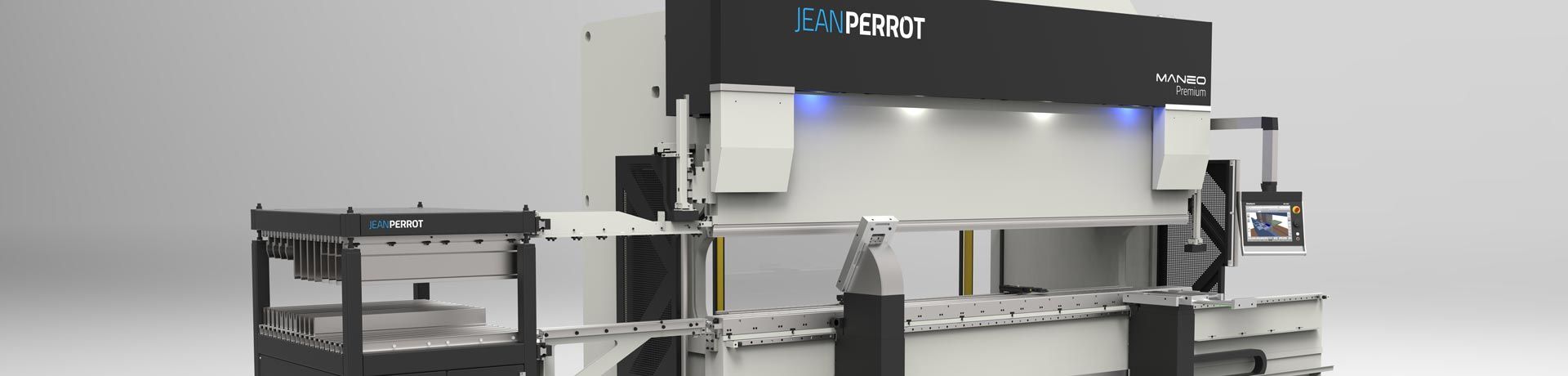

Press brakes MANEO Premium & MANEO Premium LCS

Sheet metal bending : Our press brakes MANEO Premium are high performance machines up to 2000 tons x 12 meters and more in Tandem or Tridem modes

. See More

Custom accessory equipment

We offer a wide range of standard & custom accessories in order to deliver turnkey press brake solutions adapted to your needs

See More

New electric press brake e-maneo

The essential for premium production E-MANEO premium can be distinguished by its modular, custom, and ecologically responsible design, high quality components, and ISO 9001 certified manufacturing procedures.

See More

Industry 4.0

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed a range of digitally enhanced services. Those services will assist you during the various phases of engineering development, operation, and maintenance.

See More

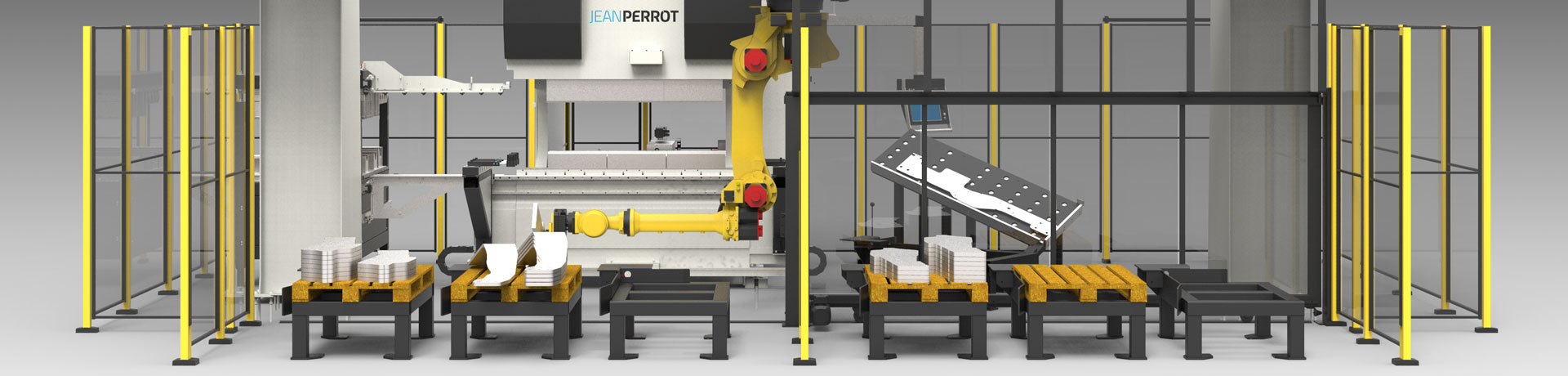

Automated bending: robotic press brake cell

We offer custom solutions to answer each of our clients' specific needs. Our automated bending cellsinclude press brake MANEO Premium LCS, robotic arms, accessories & additional modules to fit your needs.

See More

WELCOME TO JEAN PERROT

JEAN PERROT, a brand of PINETTE P.E.I. industrial engineering group, designs, manufactures and supplies sheet metal processing equipment : press brakes, automated robotic bending cells, shears, tube & profile benders, rolling machines, notching machines, punching machines…

From standard machines to turnkey automatic production lines including XXL heavy duty machines and custom tools, JEAN PERROT's team is at your disposal to define and answer all your needs related to sheet metal working machines.

‘’Innovation, expertise in sheet metal working processes and high quality of Jean Perrot’s services guarantee that your investment will be safe, mastered and adapted to your needs.’’

HGL & RGS shearing machines: quality accessible to everyone

JEAN PERROT, a brand of PINETTE industrial engineering group, designs and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube benders, rollers, notching & punching machines…

Among our shearing machine solutions, discover the HGL & RGS shears : 2 shearing machines known for their great value price / quality & performances.

Hydraulic shearing machine : HGL shear

Hydraulic shearing machine : HGL shear

From 2 to 4 meters to cut sheet metal up to 6mm thicks. This hydraulic swing beam shear is ideal for medium & small batch production. Thanks to the shearing machine controller Cybelec CybTouch 6, the HGL shear is simple to use for operators.

Mechanical shearing machine : RGS shear

Mechanical shearing machine : RGS shear

From 1.5 to 3 meters to cut sheet metal from 0.4 to 3 mm thick. RGS high speed mechanical shears are specially designed for the cutting of very thin & delicate materials such as brushed or lacquered aluminium, copper, stainless steel or zinc.

Hydraulic swing beam shear MGH

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

Among our shearing solutions, discover the hydraulic swing beam shear MGH.

MGH hydraulic swing beam shear: PERFORMANCE & SIMPLICITY

The hydraulic swing beam shear combines performance & simplicity. The robust steel welded machine frame ensure high reliability and excellent cutting quality. These shearing machines allow precise cuts with reducing deformations to a minimum. The low cutting angle on this type of shears allows to limit sheet metal twist and bow.

Thanks to the Cybelec CybTouch 6 numerical controls and its touch screen, the MGH shear is simple to operate. Apart from its performance, it complies with the CE certification, ensuring completely safe working conditions.

Features of the MGH hydraulic swing beam shear:

From 3 to 4 meters to cut sheet metal from 6 to 13 mm thick.

Standard Equipment

Cybelec CybTouch 8 numerical control device (touch screen)

Cybelec CybTouch 8 numerical control device (touch screen)- 1000mm square arm

- Ball transfer table

- Manual blade gap adjustment

- Shadow line lighting

- 1000 mm motorized ball-screw back gauge

- Centralised manual lubrication system

- 2 front arm supports of 1000 mm

- CE certification

Options

Light beam safety device for finger protection (Safety Category 4)

Light beam safety device for finger protection (Safety Category 4)- Automatic blade gap adjustment

- Square arms of 2 / 2,5 / 3 / 3,5 and 4 meters

- Front arm support of 1.5 or 2 meters

- Rear pneumatic sheet support

- Angle reporter ( adjustable guide)

Would you like further information? Whatever your project regarding shearing machines, do not hesitate to contact us or to send us an online request for quotation.

Mechanical guillotine shear CR

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

Among our shearing solutions, discover the CR mechanical guillotine, a high speed shearing machine.

MECHANICAL GUILLOTINE SHEAR CR : HIGH SPEED SHEARING

Ideal for high volume production, this shearing machine can be easily integrated into automatic shearing lines. It can cut up to 100 cuts / minute. In addition to its speed, the CR mechanical guillotine shear is economic (no hydraulics). There are designed to cut a large range of materials: steel, aluminium, inox, mica, plastics…..

Thanks to the Intuitive SIEMENS numerical controls, the CR shear is simple to use for operators. This machine also complies with the CE certification, ensuring completely safe working conditions.

Features of the mechanical shear CR:

From 2 meters to cut 2 mm thick sheet metal up to to 3 meters to cut 3 mm thick sheet metal.

Standard equipment

Standard equipment

- User-friendly Cybelec numerical controls

- Ball transfer table

- Shadow line lighting

- Clamping system with special protection for delicate sheet metal

- 500 mm motorized ball-screw back gauge

- Centralised manual lubrication system

- 1000mm square arm with back gauge

- 1000 mm front arm support

- CE certification

Options

Options

- Magnetic rear sheet support

- CNC front stops (numerically controlled)

- Motorized back gauge > 500 mm

- Mobile control panel

Would you like further information? Whatever your project regarding high performance shearing machines, do not hesitate to contact us or to send to us an online request for quotation.

Hydraulic shearing machine: HNC variable rake guillotine shear

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

Among our range of shearing machines, discover the HNC, a hydraulic variable rake guillotine shear ensuring high precision & top quality cuts.

CNC GUILLOTINE SHEAR HNC: ROBUST MACHINE FOR TOP QUALITY CUTS

The design of these shearing machines and the robust steel welded machine frame ensure high reliability and excellent cutting quality. Thanks to the intuitive numerical control device, the HNC shear is simple to use to use for operators. The NC numerical control device allows adjust automatically the cutting angle, the clearance between the blades and the position of the back gauge.

In addition to the performance of its cuts, the HNC shear also guarantees operator's safety.

Features of the hydraulic guillotine shear HNC:

From 3 meter to cut sheet metal from 6 to 25mm thick up to 6 meters to cut sheet metal from 6 to 20mm thick.

Standard Equipment

User-friendly Cybelec numerical control CybTouch 8

User-friendly Cybelec numerical control CybTouch 8- Ball transfer table

- Shadow line lighting

- Sheet metal clamping system with special protection for delicate sheet metal

- 1000 mm motorized ball-screw back gauge

- Centralised manual lubrication system

- 1000mm square arm with back gauge

- 1000 mm front arm support

- CE certification

Options

Light beam safety device for finger protection (Safety Category 4)

Light beam safety device for finger protection (Safety Category 4)- Square arms of 2 / 2,5 / 3 / 3,5 and 4 meters

- Front arm support of 1.5 or 2 meters

- Rear pneumatic sheet support with conveyor, unloading & stacking systems

- User-friendly Cybelec numerical control CybTouch 12

- Automatic retraction of the back gauge above 1 meter

- Cutting line laser lighting

- Shearing angle protractor (adjustable guide)

- Control panel on movable arm

Would you like further information? Whatever your project regarding high performance shearing machines, do not hesitate to contact us or to send us an online request for quotation.

CNC shears: High performance HNC & CR

JEAN PERROT designs, manufactures and supplies machines - standard or custom - and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shearing machines, rolling machines, bending machines, punching machines…

Among our range of shears, discover our high performance shearing solutions: the HNC hydraulic variable rake guillotine shear and the CR high speed mechanical shearing machine for high volume cutting. These premium shearing machines allows to reach optimal performance on both quality and productivity.

HNC hydraulic guillotine shear

HNC hydraulic guillotine shear

From 3 to 6 meter to cut sheet metal from 6 to 25 mm thick. The HNC shear is a hydraulic variable rake guillotine shear. This machine is perfect for applications where cut precision & quality are essential. Simple to use for operators thanks to Cybelec, Delem or Esautomotion numerical control system. Compliance with CE certification.

CR mechanical guillotine shear

CR mechanical guillotine shear

From 2 to 3 meters to cut sheet metal from 2 to 3 mm thick. The CR shear is a high speed mechanical guillotine shear adapted to high volume production. This CN machine is controlled by Cybelec numerical control. Compliance with CE certification.

JEAN PERROT industrial shears: a wide range of shearing solutions

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, benders, rolling, punching & notching machines...

Among our machine & equipment solutions, discover our industrial shears to cut metal sheets.

HIGH PERFORMANCE: HNC AND CR SHEARS

Among our range of shears, discover our high performance shearing solutions: the HNC hydraulic variable rake guillotine shear and the CR high speed mechanical shearing machine for high volume cutting. These premium shearing machines allows to reach optimal performance on both quality and productivity.

Middle range: MGH shear

We have developed an intermediate shearing machine which combines great performance and simplicity: the MGH hydraulic swing beam shear.

ENTRY RANGE: HGL ND RGS shears

JEANPERROTalso proposes entry-level shearing machines known for their great value price / quality & performances: the HGL hydraulic swing beam shear and the RGS high speed mechanical shear.

NUMERICAL CONTROLS AND SOFTWARE

We only offer CN & CNC shearing machines. Our shears are managed via numerical controls in order to optimise the productivity, ensure great versatility, to guarantee maximum accuracy and to ensure operator safety while remaining simple to use. Our industrial shearing machines are also compatible with all major CAD and CAM softwares (Computer-Aided Design and Computer-Aided Manufacturing softwares).

Pheripheral equipment & accessories

As a supplier of industrial shears & turnkey systems dedicated to the sheet metal cutting (shearing), JEANPERROT proposes a large range of accessories and functional options in order to deliver you shearing machines that perfectly suits your needs.

Large press brake accessories: customized solutions

JEAN PERROT has combined its extensive knowledge of industrial engineering with its expertise in sheet metal bending processes to design, develop and supply custom engineered accessories & options for our XXL press brake solutions: MANEO XXL, MANEO Tandem & MANEO Tridem.

PRESS BRAKE XXL EQUIPMENT ACCESSORIES

- Handling equipment: Automatic lifting beams for loading & unloading

- Motorised hoist directly fixed on the machine

- TOOLBOX XXL : modular system for tool storage, loading & unloading

- Front and back gauges up to 12 axis

- Specific front & back gauges for sheet metal bumping

- Dynamic crowning (real time adjustments) 800 tonnes/ métres

- Conveyors (loading / unloading)

- Industrial robots and other manipulators up to 2 tons

- Ball transfer tables

- Finished part removal system

- Front support arms & motorized sheet followers for heavy workpieces

- Automatic or manual laser bending line lighting

Would you like to know more?

Whatever your project regarding XXL press brake accessories, do not hesitate to contact us or to send us an online request for quotation.

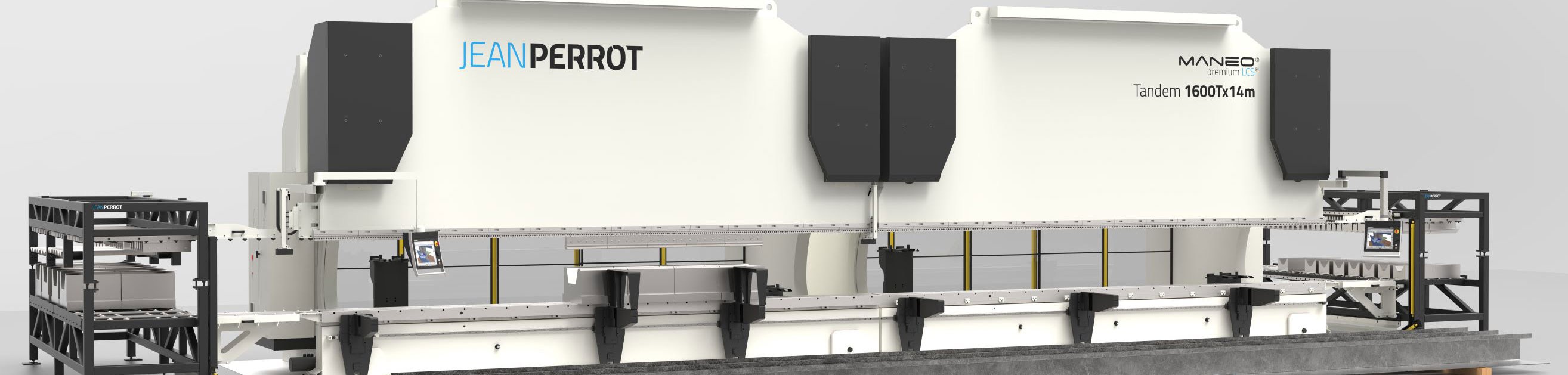

Tandem & tridem press brake for long sheet metal bending

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

Among our XXL machines dedicated to sheet metal bending, discover the MANEO Tandem & Tridem press brakes.

PRESS BRAKE MANEO TANDEM AND TRIDEM

Our MANEO press brakes can be connected in a Tandem (two press brakes connected) or Tridem (three press brakes connected) configuration. The impressive features of our Tridem press brake - up to 32 meters x 2000 tons - allow to bend long & thick sheet metal parts.

Our solutions enhance your versatility & productivity : the Tandem or Tridem modes allow you either to control all machines with one CNC or to control each machine independently. Thanks to DELEM numerical control devices, our press brakes are simple to use and ensures optimal productivity.

Highly accurate bending for long length metal sheets

The major asset of these machines lies in the bend angle accuracy along the entire bending length thanks to the combination of the hydraulique dynamic crowning system and the laser control system for measuring & correcting bend angles.

Thanks to this combination, each part is formed to the correct angle from the very first bend. You do not need trials anymore and as a consequence you save time & money. Moreover, you achieve highly accurate bending angles even for very long length metal sheets.

A large range of accessories and options

JEAN PERROT supplies a large range of equipment accessories for Tandem and Tridem press brakes among which:

- LCS: laser angle measuring & correcting system

- TOOLBOX modular system for tool sotrage, loading & unloading

- Front and back gauges up to 12 axis

- Dynamic crowning (real time adjustments) 800 tonnes/ métres

- Conveyors ( loading / unloading )

- Industrial robots and other manipulators up to 2 tons

- Ball transfer tables

- Finished part removal system

- Front support arms & motorized sheet followers

Long length bending applications

- Electric poles

- Industrial bodywork

- Trailers

- Farm equipment

- Aircraft parts

- Modular space and storage solutions (algeco type))

- Other types of long length bending applications

Would you like further information ? Whatever your project regarding long length bending machines, do not hesitate to contact us or to send us an online request for quotation.

Press brake for bending thick & long metal sheets: MANEO XXL

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

With over than 50 year of experience, Jean Perrot is a press brake supplier able to design, manufacture and deliver press brakes dedicated to large-sized & heavy duty bending applications : MANEO XXL.

XXL heavy duty press brake MANEO

Length, press force, strokes, throat gap & table / ram distance : JEAN PERROT is able to manufacture customized press brakes of large capacities (up to 12 meters long with forces up to 2000 tons). Thanks to the versatility of our machines, we can sell stand-alone press brakes or we can connect 2 (tandem configuration) or 3 (Tridem configuration) machines together to bend very long sheets. We adapt strokes, throat gap & daylight opening on request.

XXL bending machines: Large press brakes

Among our press brakes dedicated to bend long & large sheet metal workpieces, Jean Perrot has designed and manufactured a press brake with a bending length of 10 meters. This machine also features a 12 axis back gauge with a depth of 4000 mm.

Among our press brakes dedicated to bend long & large sheet metal workpieces, Jean Perrot has designed and manufactured a press brake with a bending length of 10 meters. This machine also features a 12 axis back gauge with a depth of 4000 mm.

It represents the perfect illustration of JEAN PERROT’s ability to design, manufacture & supply XXL bending machines for long metal sheets.

XXL bending machines: High tonnage press brakes

JEAN PERROT also supplies high-tonnage press brakes among which these 800 and 1000 tons press brakes.

They perfectly illustrate JEAN PERROT’s ability to design, manufacture & supply XXL bending machines for thick metal sheets.

Would you like further information? Whatever your project regarding XXL press brake solutions for thick & long metal sheet bending, do not hesitate to contact us or to send us an online request for quotation.

XXL heavy duty bending solutions

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, robotic bending cells, shears, tube & pipe benders, rollers, punching & notching machines…

Among our equipment, discover all our XXL machines & heavy duty solutions dedicated to sheet metal bending.

PRESS BRAKES MANEO XXL : Heavy duty bending machines

PRESS BRAKES MANEO XXL : Heavy duty bending machines

With over than 50 year of experience, JEAN PERROT is a press brake supplier able to design, manufacture and deliver XXL press brakes dedicated to large-sized & heavy duty bending applications : The MANEO XXL. These machines offer impressive capabilities: up to 12 meters and 2000 tons.

PRESS BRAKE MANEO TANDEM AND TRIDEM

PRESS BRAKE MANEO TANDEM AND TRIDEM

For large size bending applications (up to 32 meters), JEAN PERROT CNC press brakes MANEO can be connected in a tandem (two press brakes connected) or tridem (three press brakes connected) configuration. With the Tandem or Tridem modes you can either control all machines with one CNC or each machine independently, enhancing your versatility & productivity.

The major asset of these machines lies in the bend angle accuracy along the entire bending length thanks to the combination of the hydraulique dynamic crowning system and the laser control system for measuring & correcting bend angles.

ACCESSORIES FOR XXL BENDING MACHINES

ACCESSORIES FOR XXL BENDING MACHINES

JEAN PERROT is a supplier of turnkey solutions: we design and manufacture a large range of XXL accessories for large-capacity press brakes, tandem and tridem: XXL storage solutions, 12 axis back gauge, loading and unloading systems...

HIGHLIGHTS

News

Presse review: JEAN PERROT IN ISMR

JEAN PERROT in the pages of International Sheet Metal Review

As part of the LAMIERA 2023 trade show in Milan, where our Italian subsidiary

Tolexpo 2021

Jean Perrot at Tolexpo 2021

Come and meet us from 6th to 9th September at Global Industry at Eurexpo Lyon!

booth 6G36

You will discover our cutting edge technologies and pro...