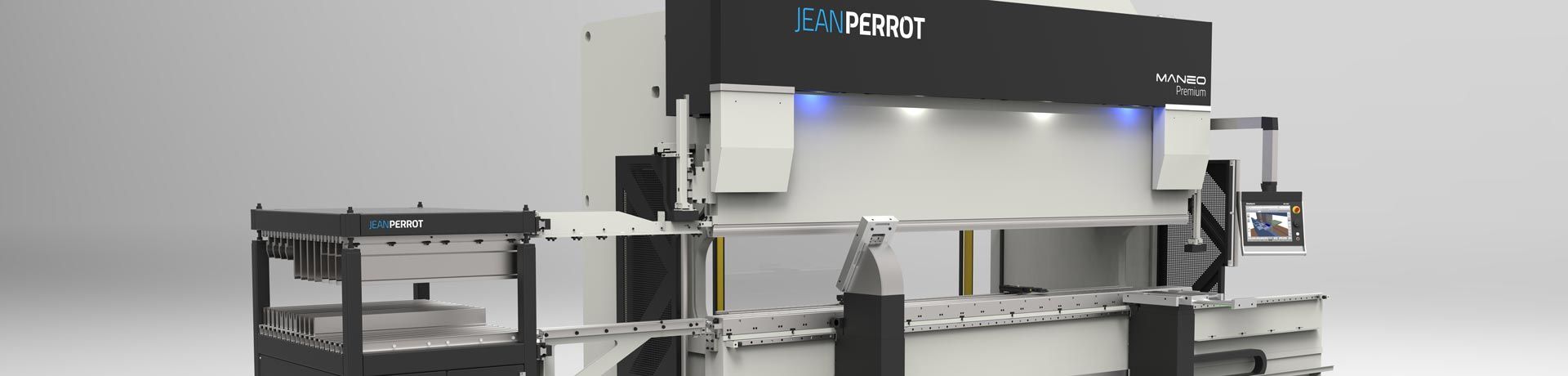

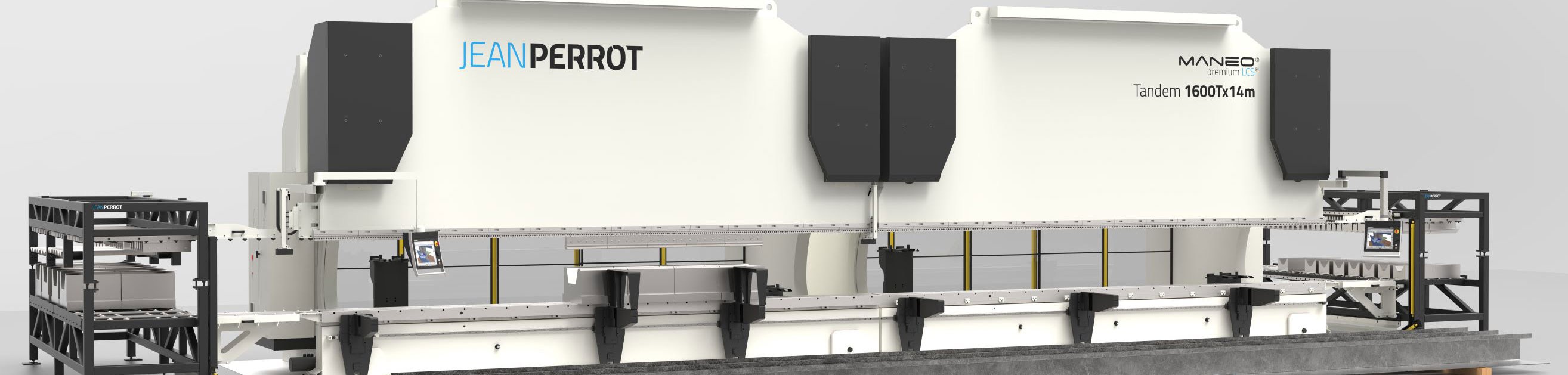

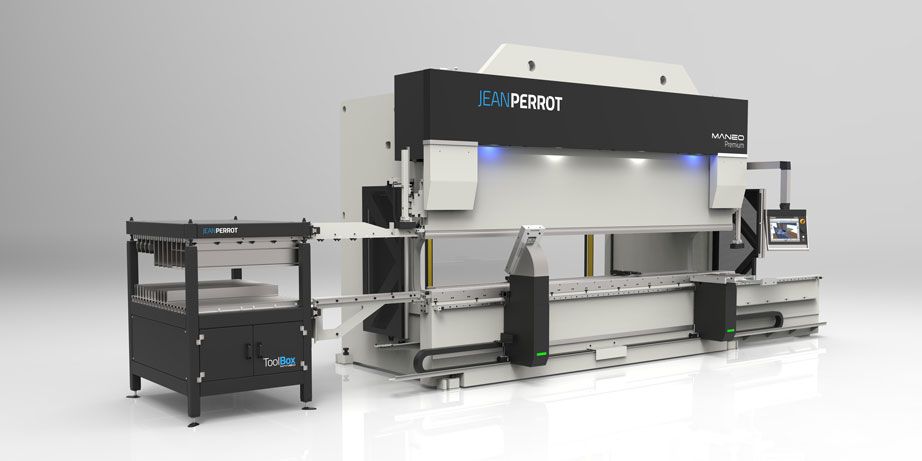

Press brakes MANEO Premium & MANEO Premium LCS

Sheet metal bending : Our press brakes MANEO Premium are high performance machines up to 2000 tons x 12 meters and more in Tandem or Tridem modes

. See More

Custom accessory equipment

We offer a wide range of standard & custom accessories in order to deliver turnkey press brake solutions adapted to your needs

See More

New electric press brake e-maneo

The essential for premium production E-MANEO premium can be distinguished by its modular, custom, and ecologically responsible design, high quality components, and ISO 9001 certified manufacturing procedures.

See More

Industry 4.0

As a pioneer in the industry 4.0 revolution, JEAN PERROT has developed a range of digitally enhanced services. Those services will assist you during the various phases of engineering development, operation, and maintenance.

See More

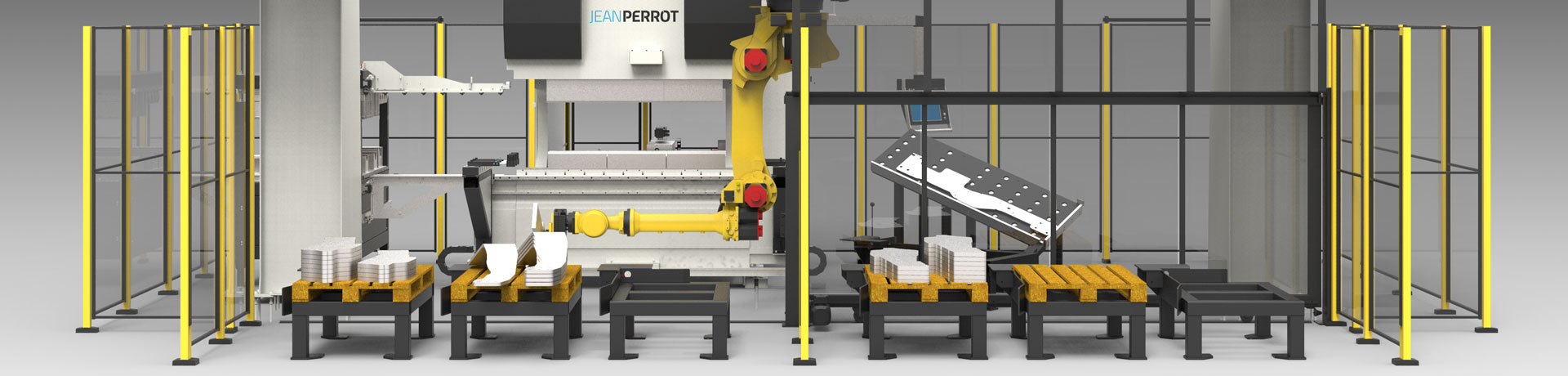

Automated bending: robotic press brake cell

We offer custom solutions to answer each of our clients' specific needs. Our automated bending cellsinclude press brake MANEO Premium LCS, robotic arms, accessories & additional modules to fit your needs.

See More

WELCOME TO JEAN PERROT

JEAN PERROT, a brand of PINETTE P.E.I. industrial engineering group, designs, manufactures and supplies sheet metal processing equipment : press brakes, automated robotic bending cells, shears, tube & profile benders, rolling machines, notching machines, punching machines…

From standard machines to turnkey automatic production lines including XXL heavy duty machines and custom tools, JEAN PERROT's team is at your disposal to define and answer all your needs related to sheet metal working machines.

‘’Innovation, expertise in sheet metal working processes and high quality of Jean Perrot’s services guarantee that your investment will be safe, mastered and adapted to your needs.’’

Jean Perrot: innovation adapted to your needs

JEAN PERROT is a brand known over the world for the reliability and the quality of its machine & systems. This reputation is a direct result of an innovation strategy that aims to develop new solutions that respond to the needs expressed by our customers. Perfect illustration of this strategy, discover our latest innovations:

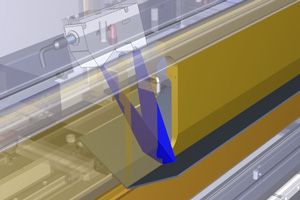

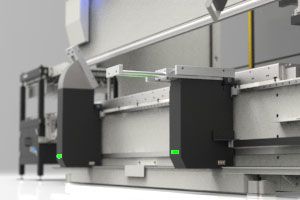

LCS angle measuring & correcting system

The LCS is a high speed laser control system to measure and adjust automatically bending angles. This patented solution ensures high precision and great quality of bending without any scrap part.

TOOLBOX : MODULAR SYSTEM FOR PRESS BRAKE TOOL STORAGE, LOADING & UNLOADING

In order to respond to the needs of our client regarding press brake tooling, JEAN PERROT has developed the ToolBox modular system simplifying press brake tool storage, loading & unloading.

HYDRAULIC DYNAMIC CROWNING

If precision is one of the most important features of a press brake, it is almost impossible to completely avoid very small imperfections compared with the bending angle originally desired, especially for heavy, long or large parts.

If precision is one of the most important features of a press brake, it is almost impossible to completely avoid very small imperfections compared with the bending angle originally desired, especially for heavy, long or large parts.

To solve this problem, our press brakes can be equipped with a dynamic crowning system. This compensation system adjusts the curvature of the lower beam automatically during the bending phase. Small imperfections are corrected in real time, thus ensuring perfect bending results.

BARCODE READER AND TRACEABILITY

JEAN PERROT has developed a traceability system and a barcode reader adapted to its press brakes. It simplifies production changeovers as well as workpiece & finished part management.

SHEET METAL FOLLOWERS

JEAN PERROT has created new motorised sheet followers to support the sheet during the bend, avoiding excessive deformation. These accessories optimize the bending performances of MANEO Premium & Premium LCS press brakes and simplify machine operators’ work.

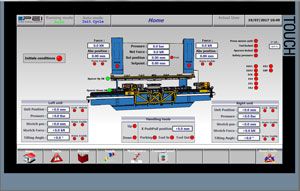

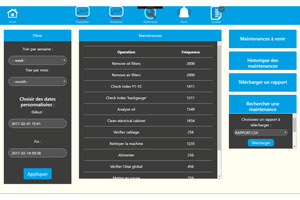

CUSTOM HMI (Human Machine Interface)

JEAN PERROT has designed custom HMI in order to simplify the work of machine operators and to optimize the productivity of our machines.

MAINTENANCE: AUGMENTED REALITY WITH JEAN PERROT SMART GLASSES

Augmented reality arrives in the industrial world, bringing new possibilities that were unthinkable until recently. Maintenance, manufacturing, training: discover JEAN PERROT smart glasses.

SHEARING MACHINE REAR CONVEYOR WITH RETURN TO THE FRONT OPTION

Industrial shears dedicated to sheet metal cutting represent an important part of our activity. In order to provide more complete solutions, we have developed a rear conveyor simplifying the operator's work and optimizing cycle times.

Jean Perrot: a complete range of services for your press brakes, shears and other sheet metal working machines

JEAN PERROT is a designer, manufacturer and supplier of sheet metal working machines known over the world for the high quality of its customer support services. From after-sales services to complex project management including training, maintenance & machine's retrofit, discover our complete range of customer support services:

SPARE PARTS AND AFTER SALES SERVICES

With JEAN PERROT, you can order your spare parts for press brakes, shears and other machines dedicated to profile and sheet metal processing. Discover also our after-sales services: part replacement, shearing blade flips….

Online catalogue : Spare parts and consumables

Check out our online catalogue to find the spare parts or consumables that you need and place your order online, by email or phone.

TRAINING

Proper use of your machines ensures optimal productivity, extends the equipment's operating life and reduces costs related to breakdowns due to poor use. For all this reasons, JEAN PERROT offers customised training services for machine operators and maintenance technicians.

All our trainers received an official accreditation.

MAINTENANCE CONTRACT

As well as insisting on the importance of carrying out weekly & monthly machine maintenance tasks, we offer our customers annual maintenance contracts for press brakes & shears.

RETROFIT BY JEAN PERROT

Find out more about the Retrofit by JEAN PERROT: a service dedicated to renovating press brakes, shears, numerical control devices, equipment accessories and other machines dedicated to the transformation of sheet metal and profiles.

CORRECTIVE MAINTENANCE - TROUBLESHOOTING

Regardless of your problem, JEAN PERROT's engineers & after-sales service technicians are there to support you and to repair your breakdown as soons as possible.

GENERAL CONTRACTOR

We benefit from the extent of the PINETTE group’s know-how in industrial engineering. Combined with our expertise of sheet metal working processes, it allows us to act as a general contractor and to carry out complex project and turnkey plants.

Tools & tool storage solutions for press brakes & shears

JEAN PERROT provides a large range of standard or custom tools for press brake and shears as well as tool storage solutions. If you need to replace parts or to retrofit a machine, please do not hesitate to contact our after sales service.

PRESS BRAKE STANDARD TOOL SOLUTIONS

PRESS BRAKE STANDARD TOOL SOLUTIONS

JEAN PERROT is not only a press brake designer, manufacturer and supplier. We also provide standard tool solutions for press brakes: punches, dies ...

PRESS BRAKE CUSTOM & SPECIFIC TOOL SOLUTIONS

PRESS BRAKE CUSTOM & SPECIFIC TOOL SOLUTIONS

In addition to standard tooling, we can help you to define, design, manufacture and provide custom engineered tools for your specific applications. From your part drawings, our design department can create customized tools dedicated to your specific production needs.

PRESS BRAKE TOOL STORAGE SOLUTIONS

PRESS BRAKE TOOL STORAGE SOLUTIONS

In order to make the operator’s work easier, to keep the workplace safer and to better protect your press brake tools, we provide tool storage solutions:

- JEAN PERROT innovation : ToolBox modular tool storage system allowing fast tool change and easy tool storage

- Tool storage cabinets

SHEARING : SHEAR BLADES

We also provide shear blades not only for JEAN PERROT's shearing machines but also for machines from all manufacturers.

Online catalogue : Shear blades quotation request

Sheet metal working machines & systems

JEAN PERROT, a brand of PINETTE industrial engineering group, is specialized in design and manufacture of standard or custom machines and turnkey systems dedicated to the sheet metal working industry. From press brakes to shears including bar, profile, pipe & tube tube benders, sheet metal rollers, notching and punching machinery, discover our comprehensive range of solutions :

PRESS BRAKES

Discover our standard and custom solutions for press brakes :

Discover our standard and custom solutions for press brakes :

- High performance press brake MANEO Premium LCS

- APHS and APHS-C press brakes and their great value price / quality

- Numerical controls (CNC) and bending software solutions

- Custom accessories & peripheral equipment

CUSTOM ENGINEERED PRESS BRAKES

Discover our custom solutions dedicated to sheet metal bending :

Discover our custom solutions dedicated to sheet metal bending :

- Automated robotic bending cells

- Semi-automatic bending press brakes

- High speed press brakes

- Custom accessories & peripheral equipment

MECHANICAL & HYDRAULIC SHEARING MACHINES

JEAN PERROT also offers sheet metal shearing machines :

JEAN PERROT also offers sheet metal shearing machines :

- High performance: HNC hydraulic variable rake guillotine shear and CR high speed mechanical shearing machine for high volume cutting

- Middle range: MGH hydraulic swing beam shear

- Entry range: HGL hydraulic swing beam shear

- Entry range: RGS high speed mechanical shears

- Numerical controls (CNC) and positioners for press brakes

- Custom accessories & peripheral equipment

XXL Machinery

As a specialist of industrial engineering and sheet metal working processes, JEAN PERROT designs and builds heavy duty press brakes (large capacity) and associated accessory equipment to work on heavy & large-size metal sheets:

As a specialist of industrial engineering and sheet metal working processes, JEAN PERROT designs and builds heavy duty press brakes (large capacity) and associated accessory equipment to work on heavy & large-size metal sheets:

- Press brake MANEO XXL

- Press brakes MANEO Tandem and MANEO Tridem

- XXL accessories & peripheral equipment

OTHER MACHINES

To cover all needs related to sheet metal working machines, JEAN PERROT can also supply:

To cover all needs related to sheet metal working machines, JEAN PERROT can also supply:

- Bar, profile, pipe & tube bending machines

- Rolling machines

- Notching machines

- Punching machines

Press brake accessories & options

As a supplier of press brakes and turnkey solutions dedicated to the sheet metal working industry, JEAN PERROT proposes press brake accessories and optional functions in order to deliver turnkey bending machines.

Press brake ACCESSORIES & OPTIONS

Handling equipment: Automatic or semiautomatic lifting beams for loading & unloading (suction cup or magnets)

Handling equipment: Automatic or semiautomatic lifting beams for loading & unloading (suction cup or magnets)- Motorised hoist directly fixed on the machine

- TOOLBOX modular tool storage system

- Front and back gauges up to 12 axis

- Dynamic crowning ( real time adjustments) 800 tonnes/ métres

- Conveyors (loading / unloading )

- Industrial robots and other manipulators up to 2 tons

- Ball transfer tables

- Finished part removal system

- Front support arms & Motorized sheet followers

- Hemming tables

- Measurement traceability with reports (compatible with LCS system)

Standard & custom press brake accessories

JEAN PERROT is committed to put all its expertise of sheet metal working processes at the service of its clients: in addition to standard solutions, we can define, design and manufacture custom engineered accessories in order to better suit your needs.

For further information, please do not hesitate to contact us or to send us an online request for quotation.

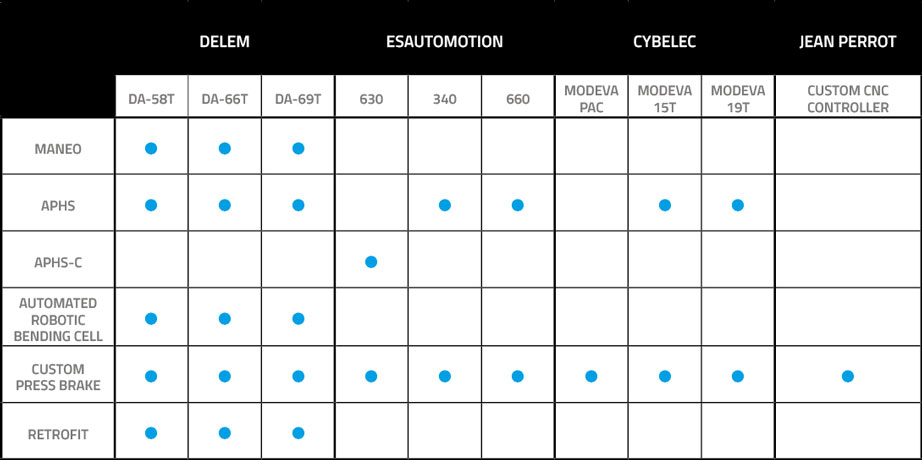

CNC Press brakes : numerical controls & softwares

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry : press brakes, automated robotic bending cells, shears, profile & tube benders, rolling, punching & notching machines…

Our CNC press brakes are managed by numerical control systems in order to optimize productivity, ensure great versatility and to guarantee the high precision bending while simplifying the work of operators and ensuring their safety.

NUMERICAL CONTROLS & SOFTWARE

Program, Control & Data processing : JEAN PERROT equipes all its press brakes with high performance CNC numerical control devices from top quality suppliers : DELEM, ESAUTOMOTION et CYBELEC.

DELEM: numerical control solutions for CNC press brake

Features & functions:

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

- USB, peripheral interfacing

- Open system architecture

- Direct navigation between programming and production

- Automatic bend sequence calculation (2D & 3D)

- Collision detection

- Optimizing the machine cycle time & minimizing the set-up time

- Easy graphical bend sequence swap and move

- Hemmed products programming

- Auto bumping calculation

- Product notes and pdf files link

- Integrated help functions, error messaging system and remote diagnosis

JEAN PERROT custom Human Machine Interface (HMI) to control the following functions:

- Tool clamping

- Light ON / OFF

- LCS laser control system

- Other functions on demand

Offline Software:

- Program preparation on standard pc & data transfer via network or USB key

- 2D / 3D product programming and visualisation directly in the software

- Import 2D (.dxf) or 3D (.step et .iges) files

- Automatic creation of tool station

- Automatic bend sequence calculation

- Printing function for bend sequences (pdf format)

- Ability to generate a production report (pdf format)

DELEM DA-58T numerical controls

DELEM DA-66T numerical controls

DELEM DA-69T numerical controls

ESAUTOMOTION: numerical control solutions for CNC press brake

Features & functions:

- 10’’,15’’ or 19’’ high resolution touch screen with multi-touch functionality

- Classic ESA interface or new interface specifically designed for multi touch screen

- 2D graphic display

- Automatic bend sequence calculation

- Manual 2D graphic identification of the best bending sequence

- Material database for predictive compensation

- USB ports

- Compatible with all major CAD software

- Direct import of tools shapes (.dxf files) and management of tool library.

Offline Software:

- Program preparation on standard pc & data transfer via network or USB key

- 2D / 3D product programming and visualisation directly in the software

- Import 2D (.dxf) or 3D (.step et .iges) files

- Automatic creation of tool station

- Automatic bend sequence calculation

- Printing function for bend sequences (pdf format)

- Ability to generate a production report (pdf format)

ESA S 630 numerical controls

ESA S 640 numerical controls

ESA S 660 W numerical controls

CYBELEC: numerical control devices for CNC press brakes

Features & functions:

- 3D or 2D programing mode

- 15’’ to 19’’ high resolution touch screen

- Intuitive touch screen interface

- 2D or 3D visualisation in simulation and production

- Automatic bend sequence calculation in 2D or 3D

- Collision detection

- User defined table for bend deduction

- Multiple view points while working

- Direct programming

- Integrated help functions, error messaging system

- On-screen finger profile drawing

- Importing 3D models

- Video-like bending process simulation

- Importing & exporting computed flat patterns as DXF files

Offline Software:

- Program preparation on standard pc & data transfer via network or USB key

- 2D / 3D product programming and visualisation directly in the software

- Import 2D (.dxf) or 3D (.step et .iges) files

- Automatic creation of tool station

- Automatic bend sequence calculation

- Printing function for bend sequences (pdf format)

- Ability to generate a production report (pdf format)

Further information:

CYBELEC ModEva Pac numerical controls

CYBELEC ModEva 15 T numerical controls

CYBELEC ModEva 19 T numerical controls

JEAN PERROT custom HMI (Human Machine Interface)

JEAN PERROT has developed a custom Human Machine Interface (HMI) to make the work of operators easier and to optimize the productivity of our machines. It allows to:

- Regrouping all of the control buttons on the same screen

- Visualizing the state of the machine and all of its actuators

- Creating preventive maintenance related pages

- Making predictive maintenance studies

Would you like further information? Whatever your need related to press brake numerical controls and CAD / CAM softwares, please do not hesitate to contact us or to send us an online request for quotation.

Compact press brake APHS-C

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry : bending, shearing, rolling, notching & punching machines…

Among our wide range of bending machines, discover the compact press brake APHS-C.

PRESS BRAKE APHS-C

The compact press brake APHS-C is known for its great value price / quality & performance. Simplicity, ease of use: this compact bending machine - from 1.25 to 4 meters long with press force from 40 to 400 tons - is particularly tailored to one-off jobs or small batch-work.

This machine aims to simplify operator’s work, thanks to the user-friendly CNC controller ESA GV and its color touch screen.

Features of our compact press brake APHS-C

ESA GV numerical control system with offline software

ESA GV numerical control system with offline software - Manual punch clamping system : Euro style or quarter turn handle

- Self-centered table for multi-V dies (4V)

- Mechanical crowning system manual or automated (CNC driven)

- Backgauge : X axis motorized and R axis manual (optionally motorised)

- Latest laser protection system to ensure operator’s safety (option)

- Front support arms vertically adjustable

Although press brakes APHS-C are standard, they can be customized on request (strokes, throat gap & daylight opening...). Moreover, we can add accessories and options: motorized sheet followers, tool storage cabinet, hydraulic clamping systems (WILA type) for tools...

Whatever your need related to sheet metal working machines, please do not hesitate to contact us or to send us an online request for quotation.

CNC press brake APHS

JEAN PERROT designs, manufactures and supplies standard or custom machines and turnkey systems dedicated to the sheet metal working industry : bending, shearing, rolling, notching & punching machines…

Among our wide range of bending machines, discover the CNC press brake APHS.

CNC PRESS BRAKE APHS

From 1.25 to 6 meters long with a press force from 40 to 600 tons, this hydraulic synchronized press brake is adapted from one-off part bending to small & medium volume series. This CNC press brake aims to simplify operator’s work thanks to the intuitive numerical control devices DELEM DA 66T or DA 69T according to your needs.

Features of our CNC press brake APHS:

- Numerical controls DELEM DA 69T with 2D graphical touchscreen and 3D visualition in simulation & production

- Numerical controls DELEM DA 69T 3D with offline software

- Manual punch clamping system : Euro style or quarter turn handle

- Self-centered table for multi-V dies (4V)

- Mechanical auto-crowning system driven by CNC machine control device

- Backgauge axis : 2 axis motorized ( X and R) and up to 6 axis (option)

- Latest laser security protection system to ensure operator’s safety

- Front support arms on linear guide rail system

Although press brakes APHS are standard, they can be customized on request (strokes, throat gap & daylight opening...). Moreover, we can add accessories and options: motorized sheet followers, tool storage cabinet, hydraulic clamping systems (WILA type) for tools...

Whatever your need related to sheet metal working machines, please do not hesitate to contact us or to send us an online request for quotation.

Middle range : press brakes APHS & APHS-C

JEAN PERROT, a brand of PINETTE industrial engineering group, is specialized in design and manufacture of standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, shears, profile & tube tube benders, rolling, notching and punching machines...

Apart from premium range bending machines, we have developed mid-range machines known for their great value price / quality & performances : press brakes APHS and APHS-C.

PRESS BRAKE APHS

From 1.25 to 6 meters long with press force from 40 to 600 tons, this hydraulic CNC press brake is adapted to bend single parts or to produce small & medium series. This CNC press brake aims to simplify operator’s work thanks to the intuitive numerical control devices DELEM DA 66 Touch or DA 69 T according to your needs.

PRESS BRAKE APHS-C

Simplicity, ease of use: these hydraulic CNC press brakes - from 1.25 to 4 meters long with press force from 40 to 400 tons - are particularly tailored to bend single parts or to produce small & medium series. User friendy numerical control device ESA GV.

Press brakes & related equipment for sheet metal bending

JEAN PERROT, a brand of PINETTE industrial engineering group, is specialized in design and manufacturing of standard or custom machines and turnkey systems dedicated to the sheet metal working industry. From press brakes to shears including profile & tube tube benders, sheet metal rollers, notching and punching machinery, we provide a comprehensive range of solutions.

Among these industrial solutions, discover our wide range of press brakes & related equipment for sheet metal bending.

HIGH PERFORMANCE / PRESS BRAKES MANEO & E-MANEO

HIGH PERFORMANCE: PRESS BRAKE MANEO PREMIUM & MANEO PREMIUM LCS

HIGH PERFORMANCE: PRESS BRAKE MANEO PREMIUM & MANEO PREMIUM LCS

In order to guarantee optimal bending performance and unmatched ease of use, JEAN PERROT has developed the next generation press brake series : MANEO Premium and MANEO Premium LCS. Machines from 2 to 12 meters long with a force from 75 to 2000 tons.

HIGH PERFORMANCE : ELECTRIC PRESS BRAKE E-MANEO PREMIUM AND E-MANEO PREMIUM LCS

HIGH PERFORMANCE : ELECTRIC PRESS BRAKE E-MANEO PREMIUM AND E-MANEO PREMIUM LCS

The essential for premium production

E-MANEO premium can be distinguished by its modular, custom, andecologically responsible design, high quality components, and ISO9001 certified manufacturing procedures.

SMALL & MEDIUM SERIES: PRESS BRAKES APHS AND APHS-C

Apart from the high performance range, we have developed an intermediate series of machines known for its great value price / quality & performances : press brakes APHS and APHS-C. From 1.25 to 6 meters long with a force capacity from 40 to 600 tons.

NUMERICAL CONTROLS AND SOFTWARES

Our CNC press brakes are managed via numerical controls in order to optimise productivity, to offer great versability, to guarantee maximal precision, to simplify the work of operators and to ensure their safety. Our bending machines are also compatible with all major CAD and CAM softwares.

Press brake accessories

As a supplier of press brakes and turnkey systems dedicated to the sheet metal working industry, JEANPERROT proposes a comprehensive range of accessories and optional functions in order to deliver bending machines that perfectly suit your needs.

HIGHLIGHTS

News

Presse review: JEAN PERROT IN ISMR

JEAN PERROT in the pages of International Sheet Metal Review

As part of the LAMIERA 2023 trade show in Milan, where our Italian subsidiary

Tolexpo 2021

Jean Perrot at Tolexpo 2021

Come and meet us from 6th to 9th September at Global Industry at Eurexpo Lyon!

booth 6G36

You will discover our cutting edge technologies and pro...