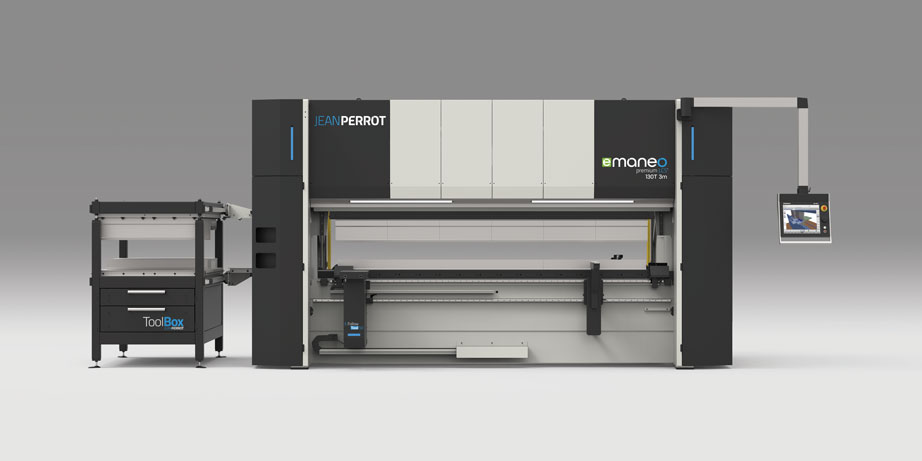

Electric press brake eMANEO Premium: high-performance bending

In order to guarantee optimal bending performance and unmatched ease of use, JEANPERROT has developed the next generation electric press brake series: eMANEO Premium and eMANEO Premium LCS.

HIGH-PERFORMANCE PRESS BRAKE series

Depending on your needs, these high-performance bending machines are available from 1630 to 4080 mm long with press force from 60 to 175 tons. These presses can operate as a standalone machine, or be integrated into a robotised bending cell.

Press Brake eMANEO Premium

eMANEO Premium, with its modular concept integrating the JEAN PERROT latest developments, and manufacturing quality (certified ISO 9001), is amongst the best machines available on the market.

All the innovations and improvements have been designed thinking of eco-responsibility, performance and productivity, evolutivity, after-sale services reactivity, and operating safety.

Press Brake MANEO LCS

Featuring the LCS - laser system to measure and control the bending angle in real-time -, eMANEO Premium LCS allows you to optimize your performances through production self-control and automation. This LCS system enables to obtain high precision and top bending quality while removing the costs related to trials.

Features of the Press Brake eMANEO:

- Table / ram opening: 500 mm

- Stroke: 250 mm

- Approach speed up to 120 mm/s

- Bending speed up to 20 mm/s

- Manual or pneumatic punch clamping system

- Manual or pneumatic die clamping system

- (Mechanical or hydraulic dynamic crowning system up to 800 t / m capacity)

- Backgauge up to 6 axes

- Front support arms

- Motorized sheet followers to support the blank during the bending phase (E Follow tools) up to 150 kg

- CNC Numerical control device DELEM DA 69 touch 2D and 3D

- CNC Numerical control device DELEM DA 69 touch 3D with offline software

- 3D & dxf files import function

- CAD & CAM software

- Rear side Safety Light Curtain

- Latest Lazersafe operator protection system allowing safe high-speed production

- Smart Tool Locator (STL)

- Laser line for “bending by marking” process (bending without backgauges)

- LCS measuring angle system

Press brake peripheral equipment & accessories:

- Robots

- TOOLBOX - modular & innovative storage system for standard & custom tools

- Other storage solutions for punches, dies and other tools.

- (Hydraulic or pneumatic hemming table)

- Conveyors and other systems to load, unload and manage metal sheets and finished parts

Bending applications:

- Single unit or small batches of high value-added parts

- Medium and large production series.

Some solid arguments

Greener | eco-responsible

- -50% energy consumption on average compared to a hydraulic press brake

- No more oil! Which means no more leak and no more drainage!

Faster

- -30% cycle time compared to a hydraulic press brake

Plug and Bend

- Simple and fast commissioning. Plug, and use your press brake immediately.

More compact

- Shorter and lighter than a hydraulic press, for an easier integration

Easy maintenance

- No more leak

- Less critical parts

- Operational safety: Upper beam in top position by default

- Bolted machine structure instead of welded

Quality

- Hydraulic or electric, it is a Maneo: the premium quality made in France

- « O » shape chassis for increased stiffness and higher accuracy

Ergonomics

- Less noise pollution

- Smart HMI

- Built-in siding for bending followers

Upgradable

- Every option can be added later

ToolBox compatible

- Positionable on the right or left side of the press, for better working conditions for your operators and better productivity.

4.0 Ready

- The eMANEO is compatible with all features and future developments of the myJEAN PERROT connected supervision

Would you like further information?

JEAN PERROT, a brand of PINETTE industrial engineering group, is specialized in the design and manufacture of standard or custom machines and turnkey systems dedicated to the sheet metal working industry: press brakes, shears, profile & tube benders, sheet metal rollers, notching, and punching machines.

Whatever your need related to sheet metal working machines, please do not hesitate to contact us or to send us an online request for quotation.