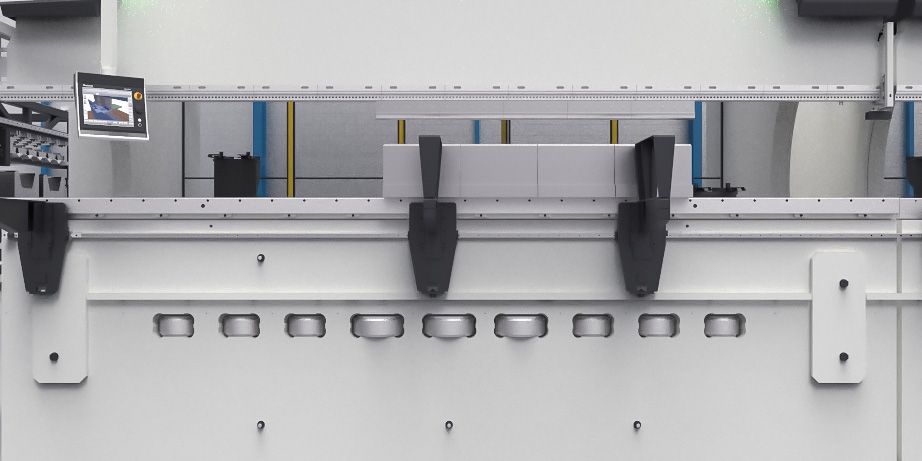

Hydraulic dynamic crowning for press brake

If precision is one of the most important features of a press brake, it is almost impossible to completely avoid very small imperfections compared with the bending angle originally desired, especially for heavy, long or large parts.

To solve this problem, JEAN PERROT press brakes can be equipped with a dynamic crowning system. This compensation system adjusts the curvature of the lower beam automatically during the bending phase. It enables to reach perfect bending results (equal & consistent angles) all along the length of the bend.

HYDRAULIC VS MECHANICAL CROWNING

The crowning system is a motorized or hydraulic axis which adjusts the curvature of the lower beam automatically during the bending phase. The crowning effort is calculated from a specific formula and from machine's setting adjustments. Depending on the type of part to be bend (bending on one side of the machine rather than bending on the center of the press brake…..) corrections can be made.

Unlike mechanical crowning system which is positioned before the bending phase, the hydraulic crowning system allow real time compensation.

Features of the CNC hydraulic crowning system:

During the bending phase, the correct crowning is calculated by the CNC and applied in real time, based on direct feedback from pressure sensors located in the press brake’s ram & bed. The multiple hydraulic crowning cylinders located within the lower bed frame allow to counter the ram deflection.

JEAN PERROT can equip its press brakes with CNC hydraulic crowning systems offering great performance : up to 800 tons per meter (option).

Would you like to know more about our hydraulic crowning system for press brakes? do not hesitate to contact us or to send us an online request for quotation.